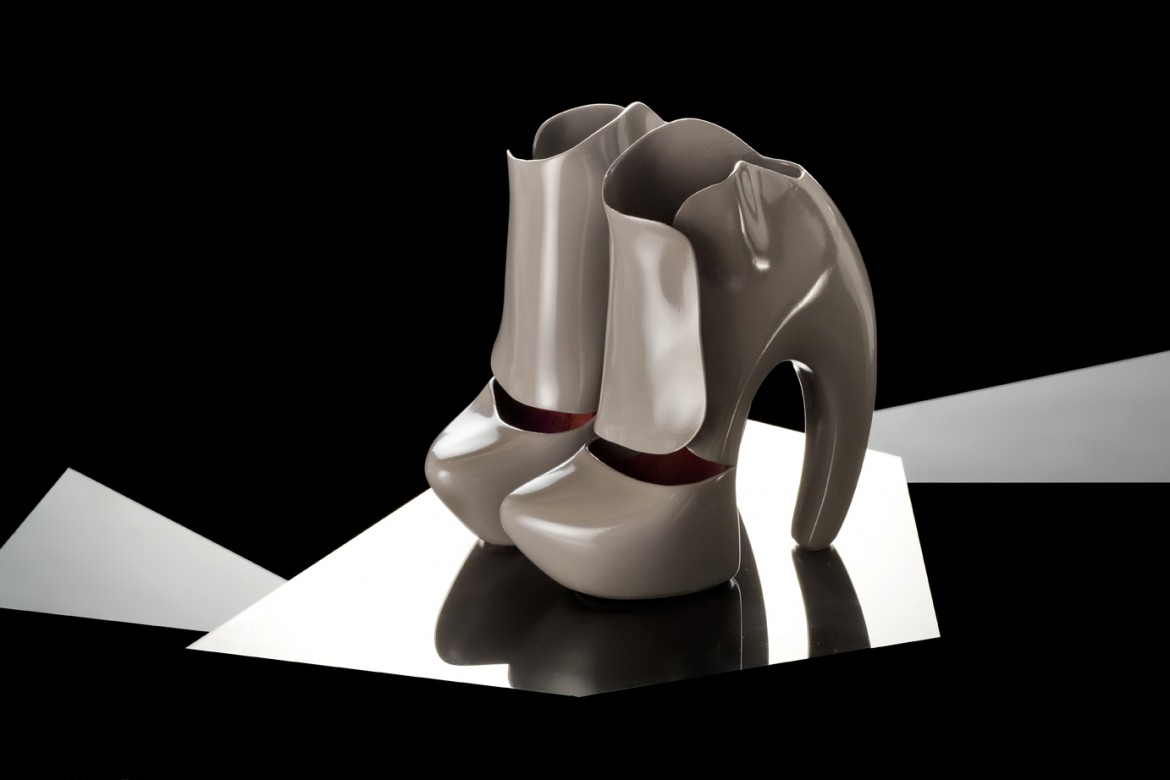

As the designer herself admits, the choice of subject might have been influenced by her difficulty in finding comfortable footwear. New technological capabilities allow anyone to scan their feet in a 3D program and order shoes that are tailor‑made for them. The present design is forward-thinking and, for the time being, remains in the conceptual stage. Nor should the choice of styles be a problem since design catalogues could be made available on the Internet.

All three pairs of shoes in the designer’s graduation project were made using different technologies (3D print, ABS vacuum shaping, and carbon fiber laminates), each of which required new construction solutions. It was not ultimately necessary, however, to divide the shoe into surface, sole, lining, and heel. The shoe has been produced in one piece with the clasps and ornaments.

The Vacuum Step 1 and 2 models are similar to a shell in form, like an organic extension of the foot. The Walking Carbon model is a “skeleton” shoe that supports the foot only at pressure points. The next concept, Vacuum Step 3, uses an interchangeable inner part, so that the shoes can be used for dancing or for rainwear. The ready‑to‑wear models are Footprint 5, which combines 3D print with a classic footwear construction, and Footprint 6, printed entirely in 3D and not subordinated to function.

All three pairs of shoes in the designer’s graduation project were made using different technologies (3D print, ABS vacuum shaping, and carbon fiber laminates), each of which required new construction solutions. It was not ultimately necessary, however, to divide the shoe into surface, sole, lining, and heel. The shoe has been produced in one piece with the clasps and ornaments.

The Vacuum Step 1 and 2 models are similar to a shell in form, like an organic extension of the foot. The Walking Carbon model is a “skeleton” shoe that supports the foot only at pressure points. The next concept, Vacuum Step 3, uses an interchangeable inner part, so that the shoes can be used for dancing or for rainwear. The ready‑to‑wear models are Footprint 5, which combines 3D print with a classic footwear construction, and Footprint 6, printed entirely in 3D and not subordinated to function.