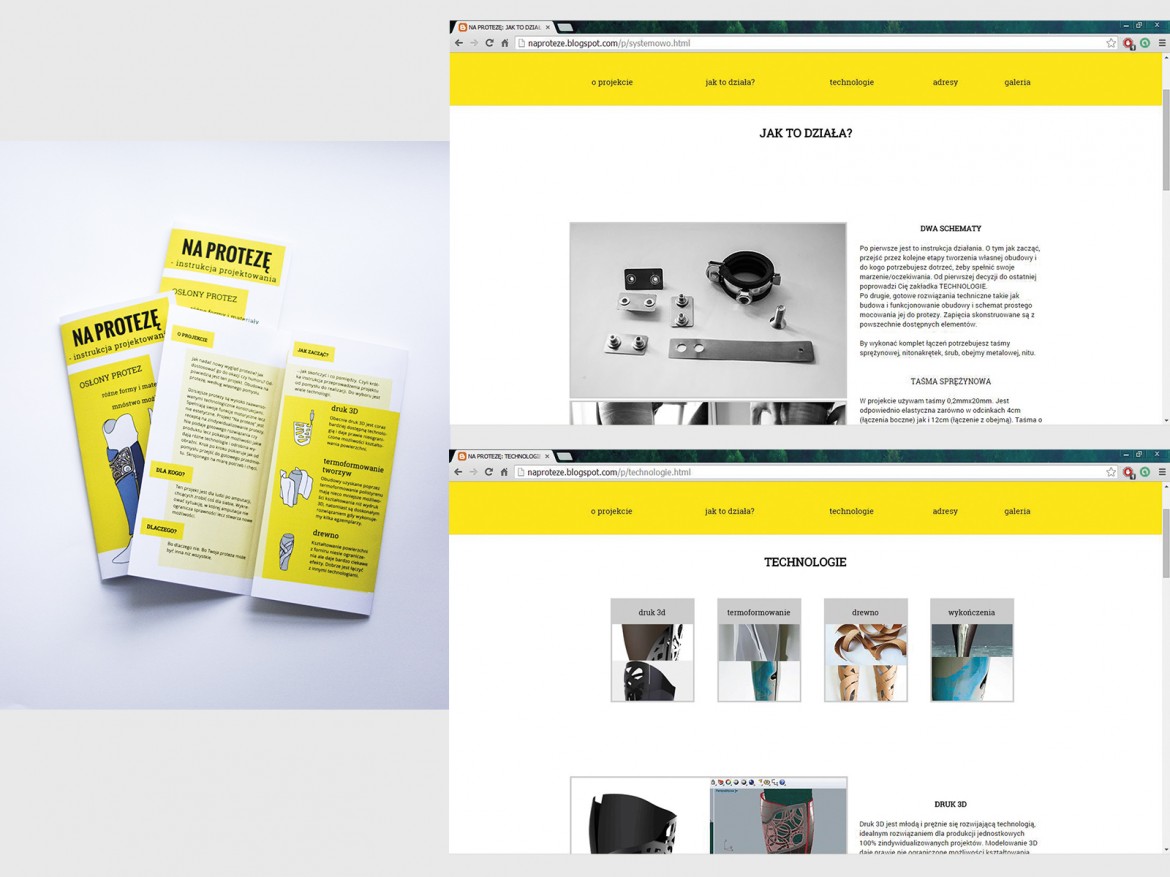

This designer falls in line with a design movement that treats the prosthesis less as an imitation of a missing organ than as a fashion element to complement an outfit. The novelty here is in allowing the user to contribute to the process of creating the cover for the prosthesis construction. This solution, on the one hand, helps to best satisfy the expectations and aesthetic preferences of individual people, and on the other, significantly reduces the price. The production, montage, and example solutions are available as open sources at naproteze.blogspot.com. Users themselves can follow precise instructions to construct and install covers for lower prostheses with the cooperation of service companies (3D printers, metalization, a tannery), whose addresses are found on the web page. The designer has produced sample covers using thermoforming technology, 3D printing, and bent beech plywood. She also shows the capabilities of leather finishing, painting, and metalization. The set and its attachment construction weigh eighty decagrams. This is a fine example of social needs and almost universally available production capabilities coming together.